Ceramic Lining

What we do

Contact Us

More Than Rubber

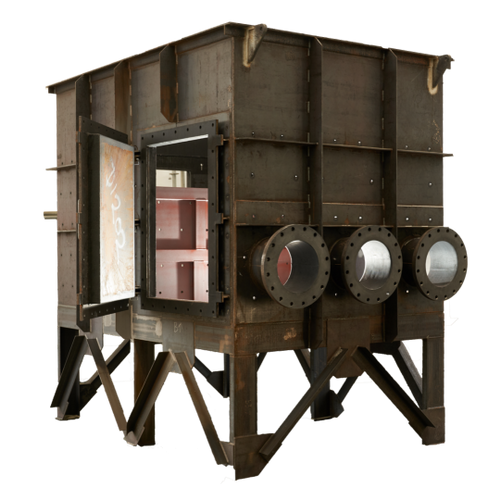

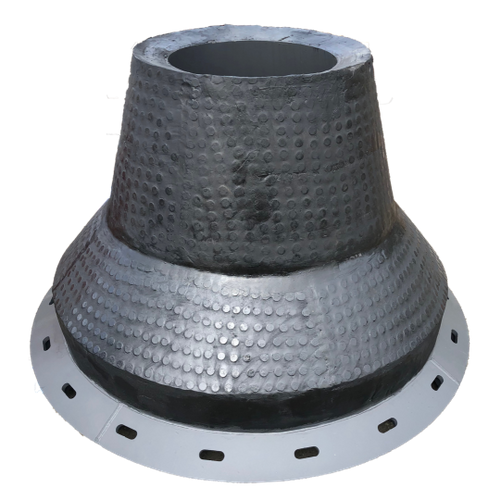

Ceramic lining is designed to maximize the life of your equipment and protect your equipment from expensive repairs and needless downtime. PRI offers ceramic lining utilizing ceramics, rubber, metal, polyurethane and combinations of these materials. We are equipped to review your process data and come up with a proposed design using various shapes, sizes and layout of ceramics to meet the specific needs of your operation.

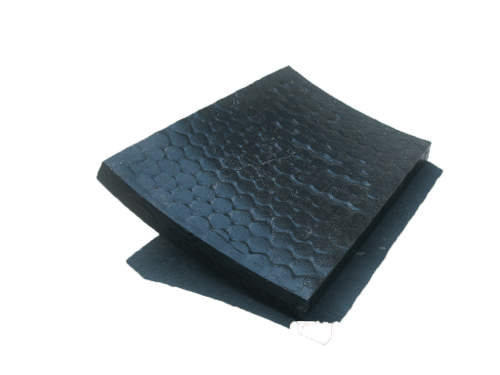

Traditionally, PRI has applied ceramics by themselves or by applying a rubber backing. The rubber backing not only improves wear characteristics, it provides vibration and noise reduction in your plant. Our rubber ceramic molded liners are the optimal solution that will provide greater toughness, reduce noise, reduce downtime and improve run life of your equipment. PRI’s rubber ceramic molded panels provide unique resistance to abrasion, while the elastic properties of other materials, like rubber, effectively absorb shock impacts.

So why choose ceramic lining over rubber?

Ceramic lining tends to have a longer product life overall and demonstrates better resistance when compared to rubber compounds when used in fine applications.

We even conducted a case study to analyze our rubber and ceramic matrix design, which you can read HERE

Custom ceramic lining with pre-engineered and standard tiles are available, with the option of using a single or double row depth of ceramic, depending on your application needs. We can manufacture all shapes and sizes of process piping and equipment.

Common applications for ceramic lining are:

- Cyclone clusters

- Hoppers and chutes

- Pipe lining

- Distributor boxes

- Transfer point lining

To find out more or if you have any questions please get in touch by submitting the form below, or via the contact details at the bottom of this page.