Rubber Lining

What we do

Contact Us

If you are interested in these services please reach out below:

More Than Rubber

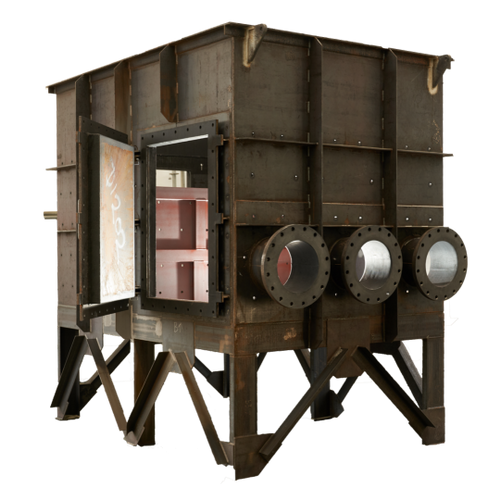

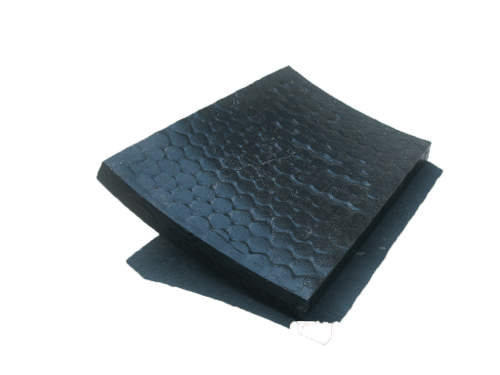

Service conditions in the mining industry are very aggressive and, in an aim to prevent damage, operators are turning to rubber lining to not only reduce noise and vibration, but also protect tanks from corrosion and impact damage.

Using rubber to line your base products not only provides abrasion, impact and corrosion resistance, but it also ensures that your products have a longer life and reduces repair costs. Since rubber lining is easy and cost-effective to replace, this in-turn lowers your overall costs of operations.

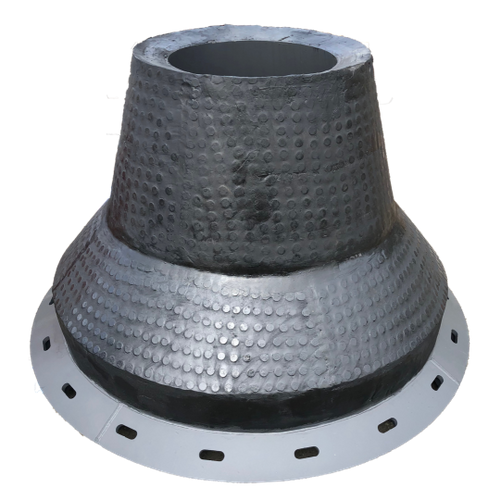

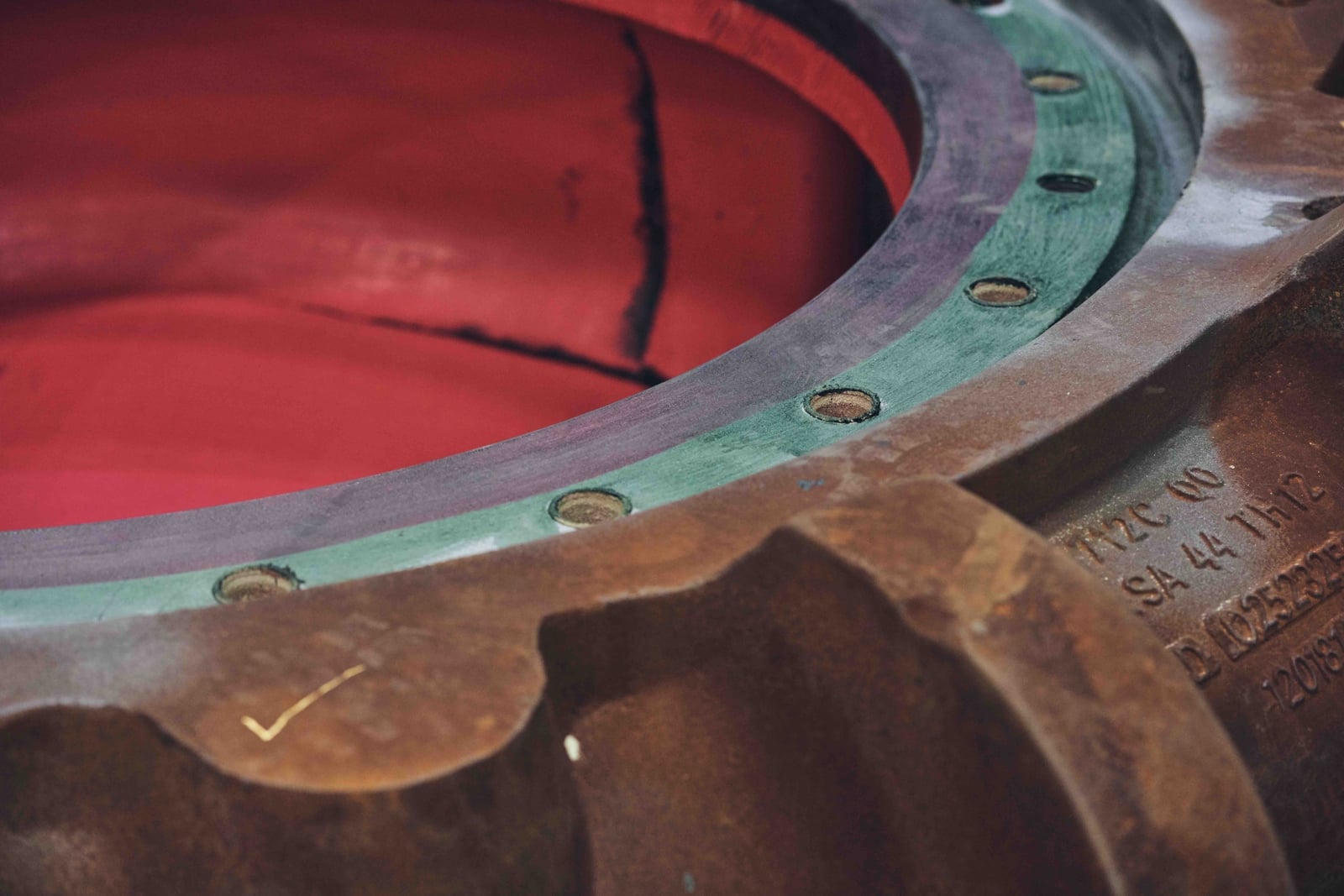

PRI is a leader in hot vulcanized, atmospheric cure and cold bond rubber lining. Over the past 23 years, PRI has rubber lined thousands of parts and components which include:

- Piping Systems

- Grinding Mill Components

- Pulp Dischargers & Trunnions

- Ion Exchange Vessels

- Pump Components

- Tanks, Boxes, Chutes, Hoppers

- Slurry Hose

- Flotation Parts

- Dart Valves & Seats

- Part Rebuilds

Our highly experienced team of rubber liners and engineers are always on-hand to provide information regarding custom compounds, various applications and general advice.

Don’t hesitate to get in touch should you have any questions. You can contact us by submitting the form below, or via the contact details at the bottom of this page.

Gallery

Here are some of the products or services PRI has been commissioned to create for various companies around the world. Most pieces are custom designed to the end users needs and requirements.